Shake, Rattle...and Retrofit - Page 2

"Alone, the skeleton [of the house] is not strong, but when you put a piece of plywood onto it, it creates shear panels that can help resist movement," says Ron Key, owner of Keycon Inc., an Eichler-focused remodeling firm on the San Francisco peninsula.

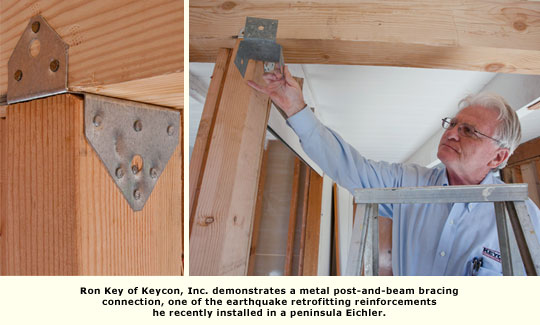

In post-and-beam construction, a wall is constructed with wood dimensional posts and beams that are attached to a metal post base or a piece of wood that is bolted to the concrete foundation. "Here, the strength is being built from the ground up," Key says.

To create that strong foundation, the house needs to be attached to something substantial. Although code requires 12-inch concrete footings, Keycon recommends 20 to 30 inches, and hitting bedrock, which offers a durable base.

Reinforcing the post-and-beam construction relies on installing new bolts through the sill and into the concrete slab. "In the old days [30 years ago], we used to put one-half-inch bolts, that were ten inches long, every 12 feet," Key says.

Today's practice is to install five-eighths-inch diameter bolts at four-foot intervals. Additionally, since bolts primarily prevent lateral or sliding movements, other types of hardware, called hold-downs, are installed at shear-panel walls to resist effects of the house lifting off the foundation during seismic movement.

The bolting and anchoring can be done from the inside or the outside of the house. After interior paneling or exterior siding is removed, concrete drills run into the slab, and then the holes are cleaned out with a wire brush and an air blower. The contractor then places an all-thread steel rod into the hole with an appropriate epoxy, which anchors it to the foundation.

It's important to replace the MCM home's original bolts because steel does not last forever. Many of the original bolts have fallen victim to rust and decay over the years, making them weak. In fact, some experts suggest replacing bolts every 30 to 40 years to ensure strength and durability.

A pressure-treated wood three-by-four plate attached to the foundation using large washers and nuts also makes a big difference in seismic resistance. Following failures observed after the 1994 Northridge earthquake, building code now requires the use of a larger, thicker, square washer in place of the small, thin, round ones that were used for many years. The larger washers help to clamp the sill from the top instead of relying only on the bolt extending through the wood sill for sliding resistance.

Another benefit to the larger washer is that it helps compensate for an over-drilling, or instances when the hole drilled for the bolt is too large, allowing the sill around the bolt to shift and split during an earthquake.

No one should be near the family fireplace during an earthquake. The heavy brick or stone can cause serious physical damage, or even death. Contractors in years past recommended strapping the chimney to the house so that both could move together during a quake.

After the Northridge quake, the Structural Engineers Society in Los Angeles looked into the best way to retrofit a chimney. They determined that retrofitting masonry chimneys with bracing or strapping is not an effective safety measure because many chimneys, even when braced or strapped, typically still fall when exposed to violent shaking.

Consider replacing your masonry chimney with a modern stud-framed one around a metal flue. Another option is a partial chimney replacement in which all of the bricks above the firebox are removed. The upper portion is then replaced by a stud-framed chimney and a metal flue. This partial replacement has been used to repair chimney damage after earthquakes and removes most of the potential life-safety issues.

If you opt to keep your original fireplace and chimney, have a plan in place to evacuate the main living area during a quake.

Your expansive windows and sliding-glass doors are potential hazards if they shatter or implode during a quake. Tempered glass, or 'safety glass,' which breaks into small pieces when struck, has been used in cars since the 1920s, but was not required in the construction of 1950s-era housing.

If you haven't done so already, find some peace of mind (and increased insulation too) by replacing your original glass with tempered glass, or install safety window film over large panes, providing a 'steel curtain' to hold shattered glass in place to protect the family from serious harm. While do-it-yourself installation of window film is possible, professional installation is recommended.